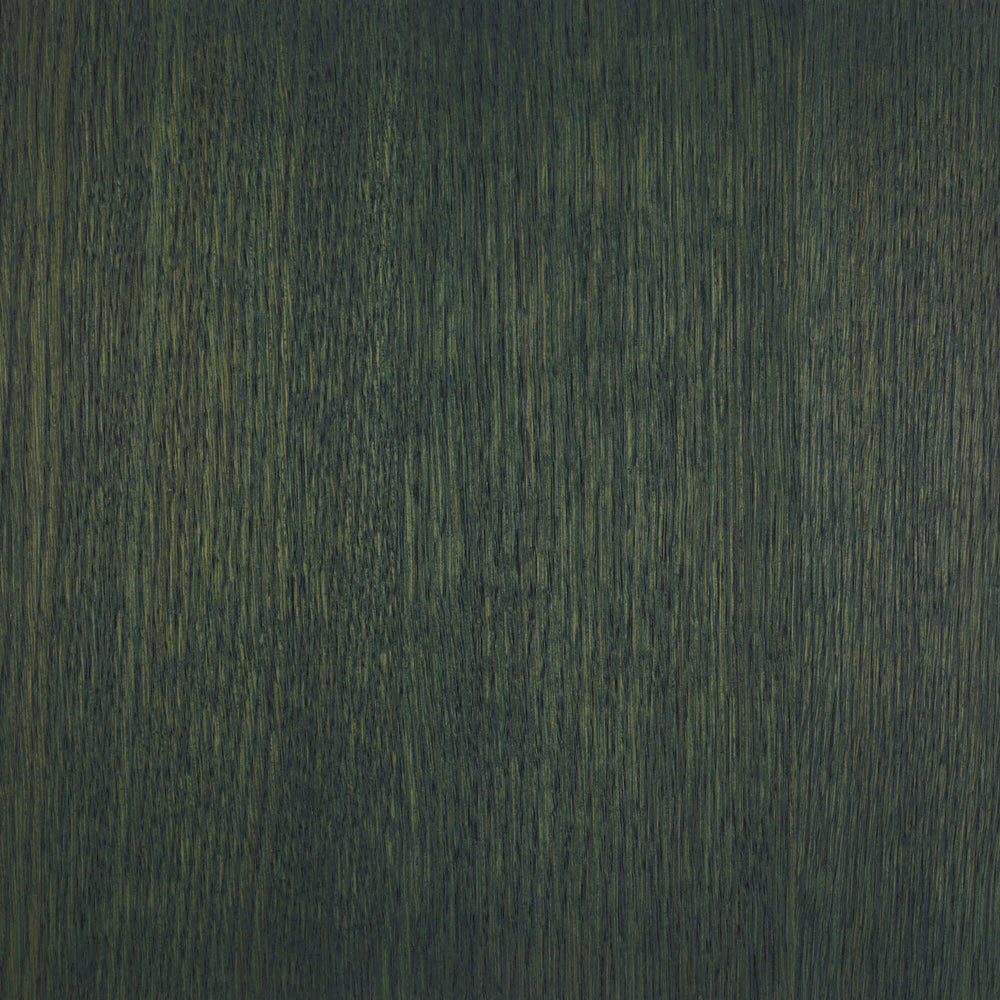

Colors shown on white oak. View additional species

Oil Plus 2C - 390 mL

Colors and protects in one single layer

Oil Plus 2C - 390 mL - Pure is backordered and will ship as soon as it is back in stock.

Couldn't load pickup availability

Shipping and Delivery

Shipping and Delivery

Free Shipping to the Contiguous U.S.

Most orders placed by 12pm CST ship same day

Good to know

How much will you need?

Please note: Calculations are estimates. Your results may vary based on species, water popping, sanding, etc...

Enter the square feet you need to cover:

Description

Description

Oil Plus 2C is the ultimate hardwax oil wood finish. It offers wood stain and durable protection in one easy-to-apply layer. Utilizing advanced molecular bonding technology, this premium wood finish provides exceptional protection against water, heat, and daily wear and tear. It is the best oil for wood furniture, hardwood flooring, tables, cabinetry, and just about any wooden surface.

Oil Plus 2C not only delivers superior durability but also ensures an easy application process. The unique molecular bonding technology means the wood oil bonds only to raw wood fibers, so unlike traditional wood stains, it will not lap line and can be locally repaired. This eco-friendly wood finish is linseed oil based, certified 0% VOC, solvent-free, and includes third-party certifications such as GREENGUARD Gold, Food Safe, and Toy Safety. Bring the beauty of nature into your home with a finish that lasts a lifetime.

Durable Wood Protection

Oil Plus 2C is the standard for single coat wood finishes. It is a durable wood finish that is wear, water, and heat resistant. Preserving the natural beauty of your wood surfaces.

Natural Look & Feel

Suitable for all wood species, Oil Plus 2C always keeps the natural look and feel of your wood by bonding to the raw wood fibers. It doesn’t build a film and will never peel or flake. Use one of our 40 standard colors or unleash your creativity by mixing your own custom color, the possibilities are endless.

Easy to Use

Find the joy in wood finishing thanks to a simple and easy application process. Oil Plus 2C bonds to raw wood and not itself, meaning it doesn’t lap line and can be easily spot repaired, making maintenance a breeze. Properly cared for surfaces will last a lifetime.

1-Layer Technology

Save time with Oil Plus 2C’s unique molecular bonding technology that colors and protects your interior wood in just one layer. Ready for light use after one day and 80% cured after two days.

Certified 0% VOC

Oil Plus 2C is eco-friendly and sustainable, featuring a linseed oil base and multiple third-party certifications, including GREENGUARD Gold, 0% VOC, Food Safe, and Toy Safety. The 100% solid formulation is solvent-free and VOC-free and boasts an exceptionally high spread rate.

Specifications

Specifications

-

Spread Rate

-

Spread Rate by Packaging

-

Cure Time

-

VOC Content

-

Color Options

-

Dilutable

-

Shelf Life

-

Combustion warning

Certifications

Certifications

Oil Plus 2C - 390 mL has achieved the following certifications:

Downloads

Downloads

Helpful links and documents to learn about the product.

Instructions

Instructions

Unlike traditional wood finishes, Rubio Monocoat products are easy to work with, making it an excellent choice for your wood finishing needs.

For detailed guidance, refer to the following resources:

For additional support, please visit our Help Center or reach out to our friendly support team. We're always here to assist you!

One order. One tree.

For every order, Rubio Monocoat USA will plant a tree at a U.S. planting site. Partner with us and plant an additional verified tree.

Payment & Security

Payment methods

Your payment information is processed securely. We do not store credit card details nor have access to your credit card information.